Industrial safety nets

In an industrial environment, safety is of paramount importance. Whether it’s a construction site, a warehouse, or any manufacturing facility, ensuring the safety of workers and protecting valuable equipment should never be overlooked. Industrial safety nets are a highly effective and practical solution to prevent accidents, protect property, and ensure a secure work environment.

At Open view invisible grills , we provide durable and high-quality industrial safety nets that offer superior protection against a range of hazards. With years of experience in the industry, we understand the unique safety requirements of industrial settings and deliver tailored solutions that meet your specific needs.

Key Highlights

- Durability and Strength: Industrial safety nets are constructed with high-strength materials like nylon, polyethylene, and polypropylene, ensuring they can withstand harsh weather conditions and high-impact forces. Designed for long-lasting use, they provide reliable protection over time.

- Customizable Solutions: Whether for scaffolding, warehouses, rooftops, or construction sites, our industrial safety nets can be tailored to fit your specific needs. We offer bespoke sizes, shapes, and designs to accommodate unique site layouts and safety requirements.

- Enhanced Worker Safety: The primary goal of industrial safety nets is to protect workers from falls, debris, and falling materials. By acting as a physical barrier, these nets help reduce the risk of accidents and injuries, ensuring a safer working environment.

- Weather and UV Resistance: Made from weather-resistant materials, our safety nets are built to endure the elements. They remain durable and effective under extreme temperatures, rain, and sun exposure, making them perfect for outdoor industrial applications.

- Low Maintenance: Industrial safety nets require minimal maintenance due to their robust construction. This translates to reduced upkeep costs and hassle-free operation, making them a practical and long-term safety investment.

- Compliance with Safety Standards: Our safety nets meet local and international safety regulations, helping you stay compliant with workplace safety standards. They provide peace of mind by ensuring your facility meets industry safety guidelines.

- Versatile Applications: Ideal for a wide range of industrial applications, from construction sites and scaffolding to warehouses and factories, our safety nets are versatile and adaptable to various environments where safety is critical.

- Easy Installation: Designed for quick and easy installation, our industrial safety nets minimize downtime during setup. Our professional installation team ensures that the nets are securely in place, providing maximum protection from day one.

How to Choose the Perfect industrial safety nets

- Assess the Purpose and Use: Before selecting a safety net, identify the specific hazards and risks present in your environment. Consider whether the net will be used for fall protection, debris containment, or for securing materials. This will help you choose the appropriate type and strength of the net.

- Material Strength and Durability: Industrial safety nets need to be made from durable materials that can withstand extreme weather conditions, wear and tear, and heavy-duty use. Popular materials include nylon, polyethylene, and polypropylene. Choose a material that offers both strength and longevity, considering factors such as UV exposure, chemicals, and temperature extremes at your worksite.

- Mesh Size and Load Capacity: The mesh size determines the net’s ability to catch falling objects, debris, and materials. For applications where larger materials might fall, opt for a net with a smaller mesh size. Ensure that the net's load capacity meets or exceeds the weight and volume of the materials it will be protecting against.

- Compliance with Safety Standards: Ensure that the safety nets meet local and international safety standards. Industrial safety nets should comply with OSHA, ANSI, or other relevant safety regulations in your area. This guarantees that the net is designed to provide the necessary protection and withstand required testing.

- Size and Coverage: Choose a net that will adequately cover the intended area. Measure the perimeter or space where the net will be installed, ensuring the net covers the full area to prevent any gaps. A custom-sized net might be necessary for more complex or large-scale installations.

- Installation and Maintenance: Consider the ease of installation and maintenance when choosing a safety net. Some nets are easier to install with minimal tools, while others may require professional assistance. Opt for a net that is not only easy to set up but also requires minimal maintenance over its lifespan.

Factors to Consider Before Installing industrial safety nets

Installing industrial safety nets is a crucial step in safeguarding workers, materials, and the environment on construction sites and industrial premises. Proper planning and considerations are necessary to ensure the safety and effectiveness of the safety nets. Here are the key factors to consider before installation:

- Purpose of the Safety Net: The first step in selecting the right industrial safety net is to clearly define its purpose. Will it be used for fall protection, debris containment, or as a barrier to prevent access to hazardous areas? Understanding the net's purpose will help determine the best type, strength, and mesh size required.

- Site Assessment and Risk Analysis: Conduct a thorough assessment of the site to identify the hazards that the safety net needs to address. Look for potential risks such as falling debris, workers working at heights, or dangerous machinery nearby. By evaluating these risks, you can ensure that the net meets the safety requirements and is appropriately designed for the specific site.

- Compliance with Regulations and Standards: Ensure that the safety net complies with local and international safety standards, such as OSHA, ANSI, or other relevant industry guidelines. These standards define the strength, material, and installation methods needed to ensure the net performs as required in case of an emergency. Failing to meet these standards could result in non-compliance and increased risk.

- Material Selection: The material of the safety net plays a significant role in its strength, durability, and resistance to environmental elements. Popular materials include nylon, polyethylene, and polypropylene. Consider the factors like UV resistance, chemical exposure, temperature extremes, and weather conditions at your site. Make sure the material is strong enough to withstand the forces it will face, such as impact from falling objects.

- Mesh Size and Load Capacity: The mesh size should be chosen based on the size and type of objects it will catch. Smaller mesh sizes are ideal for containing small debris or objects, while larger mesh sizes are suitable for larger materials. In addition, the net's load capacity should be carefully considered to ensure it can support the weight of debris or falling items.

- Environmental Conditions: The safety net will be exposed to the elements, so you need to consider environmental factors such as sunlight, rain, wind, and temperature. Nets made from weather-resistant materials such as UV-protected polyethylene can offer long-lasting durability, preventing deterioration from prolonged exposure to the elements.

- Size and Coverage Area: Accurately measure the area where the safety net will be installed. Ensure that the net will fully cover the designated space, leaving no gaps where debris or objects can fall through. The net should extend far enough to accommodate potential movements or changes in the environment, such as winds that might shift the net.

Importance of industrial safety nets

Industrial safety nets are essential for maintaining a safe work environment in various sectors, especially in construction, manufacturing, and other high-risk industries. These nets offer critical protection against accidents and injuries, ensuring the safety of both workers and the surrounding area. One of the primary functions of industrial safety nets is to prevent workers from falling, especially in construction, scaffolding, and high-rise environments. They act as a reliable safety barrier, reducing the risk of fatal falls and serious injuries. The nets catch workers who may slip or lose their balance, providing an additional layer of protection when other safety measures, such as guardrails, may not be sufficient.Industrial sites often involve heavy machinery and the use of tools that can cause debris to fall. Safety nets help catch falling materials, preventing damage to equipment, surrounding structures, and vehicles on the ground. They also protect passersby from injury due to falling objects, making them a crucial element of site security.Investing in industrial safety nets is a cost-effective way to reduce workplace accidents and injuries. The cost of installing safety nets is relatively low compared to the potential costs of medical expenses, legal liabilities, and compensation for workplace injuries. By preventing accidents, businesses save money in the long run and improve their reputation as a responsible employer.When workers know that their safety is a priority and that they are well-protected, they feel more confident and motivated to perform their tasks. This increased confidence can lead to enhanced productivity and a positive work environment. In industrial settings, safety nets provide vital protection when workers are conducting inspections or maintenance activities at elevated heights. Whether it’s inspecting tall structures, repairing machinery, or servicing overhead systems, safety nets create a secure environment for workers to complete their tasks without the constant fear of falling.

Why Hyderabad Needs industrial safety nets

Hyderabad, a major industrial and commercial hub in India, is home to numerous construction sites, manufacturing units, and industrial complexes. With rapid urbanization and development, the city’s industrial sectors face an increasing demand for enhanced safety measures to protect workers, infrastructure, and surrounding areas.Hyderabad’s booming construction industry, driven by rapid urbanization and infrastructure projects, creates a high demand for safety measures. Industrial safety nets are crucial in protecting workers on construction sites, especially in high-rise buildings, bridges, and large-scale infrastructure projects. They prevent falls and injuries while also securing falling debris that could harm workers and pedestrians below.

The city’s skyline is changing with the rise of high-rise residential, commercial, and mixed-use buildings. These structures pose a significant risk to construction workers who work at elevated heights. Industrial safety nets provide essential fall protection, reducing the chances of accidents and ensuring worker safety at every stage of construction.

Hyderabad is home to a growing number of manufacturing plants, factories, and industrial hubs. From pharmaceuticals and textiles to automotive and electronics, various industries operate here. Safety nets are essential in these environments to protect workers from potential hazards such as falling objects, machines, and tools. They ensure that workers remain safe while performing their tasks, especially in high-risk areas like assembly lines, warehouses, and storage units.

Types of industrial safety nets available

- Fall Arrest Nets : Fall arrest nets are primarily used in construction sites, especially in high-rise buildings and elevated areas. These nets are designed to catch workers in the event of a fall, preventing serious injuries or fatalities. Made from high-strength materials such as nylon or polypropylene, fall arrest nets provide a critical layer of protection against falls from significant heights.

- Debris Nets : Debris nets are used to contain and prevent debris, tools, or other materials from falling from construction sites, particularly in high-rise or scaffolding work. These nets are usually installed around the perimeter of a building or scaffolding to stop items from dropping onto the workers below or into public spaces. They help maintain a safe working environment by reducing the risk of accidents caused by falling objects.

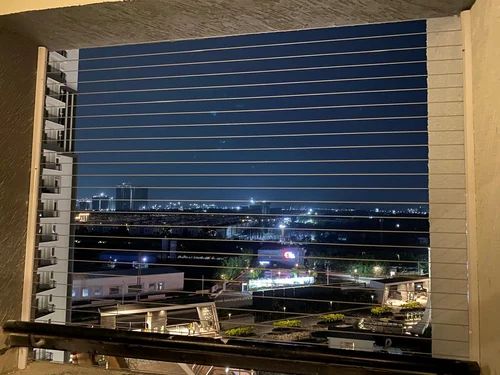

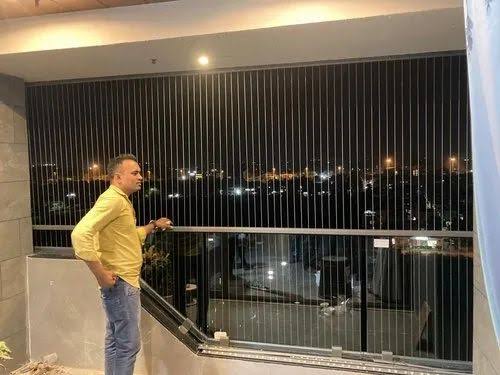

- Vertical Safety Nets : Vertical safety nets are installed to safeguard workers working on the sides of buildings or tall structures. They are especially important for workers handling materials or tools at significant heights. These nets are fixed vertically along the edges of buildings, providing a protective barrier against falls. Vertical safety nets are typically used in construction, maintenance, and cleaning tasks on skyscrapers, bridges, or towers.

- Horizontal Safety Nets : Horizontal safety nets are placed horizontally across an area to prevent falls from floors, roofs, or scaffolding. These nets are used to create safe working platforms, particularly in areas where workers are performing tasks like roofing or flooring at height. They provide a large safety area and are designed to catch falling workers or tools, reducing the risk of injury or accidents.

- Anti-Climb Nets : Anti-climb nets are installed on the perimeter of construction sites, factories, or industrial zones to prevent unauthorized access and protect workers from accidental falls. These nets are made from strong materials such as steel wire and are designed to prevent people or animals from climbing over the protective barriers, ensuring safety within the premises.

FAQ

Industrial safety nets are protective barriers designed to prevent falls, accidents, and injuries in hazardous work environments. They are typically used in construction, manufacturing, and other industrial sectors where workers are exposed to high-risk activities at height. These nets catch falling objects or workers, providing a critical safety measure.

There are several types of industrial safety nets available, including Fall Arrest Nets, Debris Nets, Vertical and Horizontal Safety Nets, Machine Safety Nets , Scaffolding Safety Nets

Yes, many industrial safety nets are designed to withstand various weather conditions, including rain, snow, and high winds. However, it’s important to choose nets that are made from materials suitable for the specific environment. For example, UV-resistant nets are ideal for outdoor use in areas with high sun exposure.

Yes, industrial safety nets can be used in both indoor and outdoor environments. They are commonly used in warehouses, factories, and other indoor industrial settings to protect workers from falls or accidents involving machinery and other hazards.